In this research it has been studied the effect of heat treatment temperature on microstructure and hardness properties of casted Ti-6Al-4V ELI alloy. After calculation of material balance to obtain this alloy composition raw materials were melted using single arc melting furnace flowed with argon gas and melted alloy was casted.

ATI Ti-6Al-4V Grade 5 alloy is used in the annealed condition and in the solution treated and aged condition.

Ti 6al 4v heat treatment. Temperatures to about 800F 427C. ATI Ti-6Al-4V Grade 5 alloy is used in the annealed condition and in the solution treated and aged condition. Compressor blades discs and rings for jet engines.

Airframe and space capsule. Titanium 6Al-4V 6246 6-2-4-6 BC Beta-C Heat Treating We have over 20 years experience processing titanium and other high-alloys. Our metallurgical background enables us to customize the heat treat cycle to produce optimum mechanical properties to meet demanding specifications.

Electron beam melting EBM is a metal powder bed fusion additive manufacturing AM technology that is used to fabricate three-dimensional near. Ti 6Al-4V is known as the workhorse of the titanium industry because it is by far the most common Ti alloy accounting for more than 50 of total titanium usage. It is an alphabeta alloy that is heat treatable to achieve moderate increases in strength.

Ti 6Al-4V is recommended for use at service temperatures up to approximately 350C 660F. Able to double as the stabilization heat treatment. Alpha-beta alloys that are lean in beta such as Ti-6Al-4V can be air cooled from the annealing tempera-ture without impairing their stability.

Furnace cooling slow cooling how - ever may promote formation of Ti 3Al which can. Titanium 6Al-4V Solution Treated Aged STA Plate per AMS 4904 Titanium Solution Treated and Aged plate and sheet per AMS 4904 is a specialty at Flight Metals. This aging treatment process increases the strength and mechanical properties by hardening for critical applications.

In this research it has been studied the effect of heat treatment temperature on microstructure and hardness properties of casted Ti-6Al-4V ELI alloy. After calculation of material balance to obtain this alloy composition raw materials were melted using single arc melting furnace flowed with argon gas and melted alloy was casted. To obtain maximum creep resistance and stability in the near-α alloys Ti-8Al-1 Mo-1 V and Ti-6Al-2Sn-4Zr-2Mo a duplex annealing treatment is employed.

This treatment begins with solution annealing at a temperature high in the α-β range usually 25 to 55C 50 to 100F below the β transus for Ti-8Al-1Mo-1Vand 15 to 25C 25 to 50F below the α-β transus for Ti-6Al-2Sn-4Zr-2Mo. For the deposited Ti-6Al-4V titanium alloy the metallographic structure is the wechsler structure dominated by martensitic alpha needle. After heat treatment at 950 CAC1 h 540 CAC4 h the microstructure changes into the net basket structure.

After 950 CFC1 h heat treatment the microstructure of the alloy changed into duplex structure some of the alpha phase in the alloy are. Titanium alloys need post-treatments like the hot isostatic pressing HIP and heat treatment to reduce some casting defects. For these reasons in order to apply to the Ti-6Al-4V alloy fabricated by VAR process on industries it needs to improve their mechanical properties at room temperature and elevated temperature by aging.

Heat treatment of L-PBF Ti-6Al-4V samples includes annealing at 630-680С for 2-4 h to relieve the stresses followed by annealing in vacuum 1594 or annealing at 800С for several hours in. Treatments on impact toughness of Ti-6Al-4V alloy produced by conventional ingotwrought or casting routes 146. The work done by Meyer et al.

Suggests that heat treatment of mill-annealed Ti-6Al-4V alloy gives a range of impact toughness however furnace cooling from the β or α β phase. Yang and Gabbitas have shown that Ti6Al4V alloy rods prepared by powder compact extrusion with 04 wt oxygen can be heat treated in the α β phase field to enhance the ductility 4. This technology has been demonstrated in a laboratory research scale and on prototype parts.

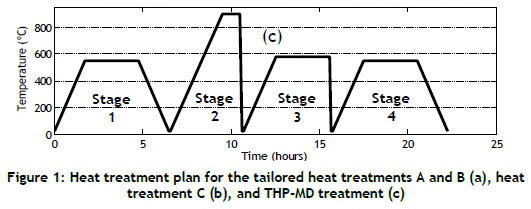

This program effort would use existing technology to develop an optimized heat treatment process for AM Ti-6Al-4V alloys quantitative process-structure-property relationships utilizing simple shaped tensile and fatigue specimens. There is hardly any prior work related to post processing heat treatment of EBM built Ti6Al4V other than HIP treatments. The variety of heat treatment cycles and its influence in microstructure and properties studied in this research gives a clear understanding on how to tailor final microstructures and select the optimal heat treatment process.

A framework for the prediction and control of microstructure evolution during heat treatment of wrought alphabeta titanium alloys in the two-phase field was established via carefully controlled induction heating trials on Ti-6Al-4V and accompanying mathematical modeling based on diffusion-controlled growth. Induction heat treatment consisted of heating to and soaking at a peak temperature T p.