For every 10 tonnes of sugarcane crushed a sugar factory produces nearly three tonnes of wet bagasse. Yet this potential remains by and large unexploited.

Average sugarcane production over the past five years was 23 million metric tons which yielded 2 243 700 metric tons of sugar from about 411 000 ha planted to sugarcane Philippine Sugar Commission 1985.

Sugarcane bagasse production in the philippines. Sugarcane Bagasse Charcoal Making Machine in the Philippines Most of us consider that the sugarcane bagasse is the waste of sugar industry especially for the southeast countries like Philippine Malaysia India and Thailand where the bagasse are in need to find a way for recycling. But how do we to deal with these wastes. Just throw it anywhere.

The Philippines Sugarcane Industry contributes no less than P70 Billion to our economyannually. Out of the total land area of about 30 million hectares sugarcane is planted toabout 422500 hectares in the Philippines with about 62000 farmers. There are 29operating raw mills with combined crushing capacity of 185000 metric ton cane per day.

The Philippine sugar industry the countrys oldest and leading export earner is a very important sector of the economy. Average sugarcane production over the past five years was 23 million metric tons which yielded 2 243 700 metric tons of sugar from about 411 000 ha planted to sugarcane Philippine Sugar Commission 1985. Only 13 bagasse to process same ton of cane stalk.

25 Lkgha more sugar than the Philippines. Commonly stated that sugar production starts in the field via the sugarcane plant. It is estimated that 117 million tonnes of sugarcane trash is recoverable as a biomass resource in the Philippines.

In addition 64 million tonnes of surplus bagasse is available from sugar mills. There are 29 operating sugar mills in the country with an. Sugar production in the Philippines for crop year 20192020 is projected to reach 21 million tons amid higher domestic consumption and as local prices remain higher than global levels Fitch Solutions Macro Research said in its industry trend analysis.

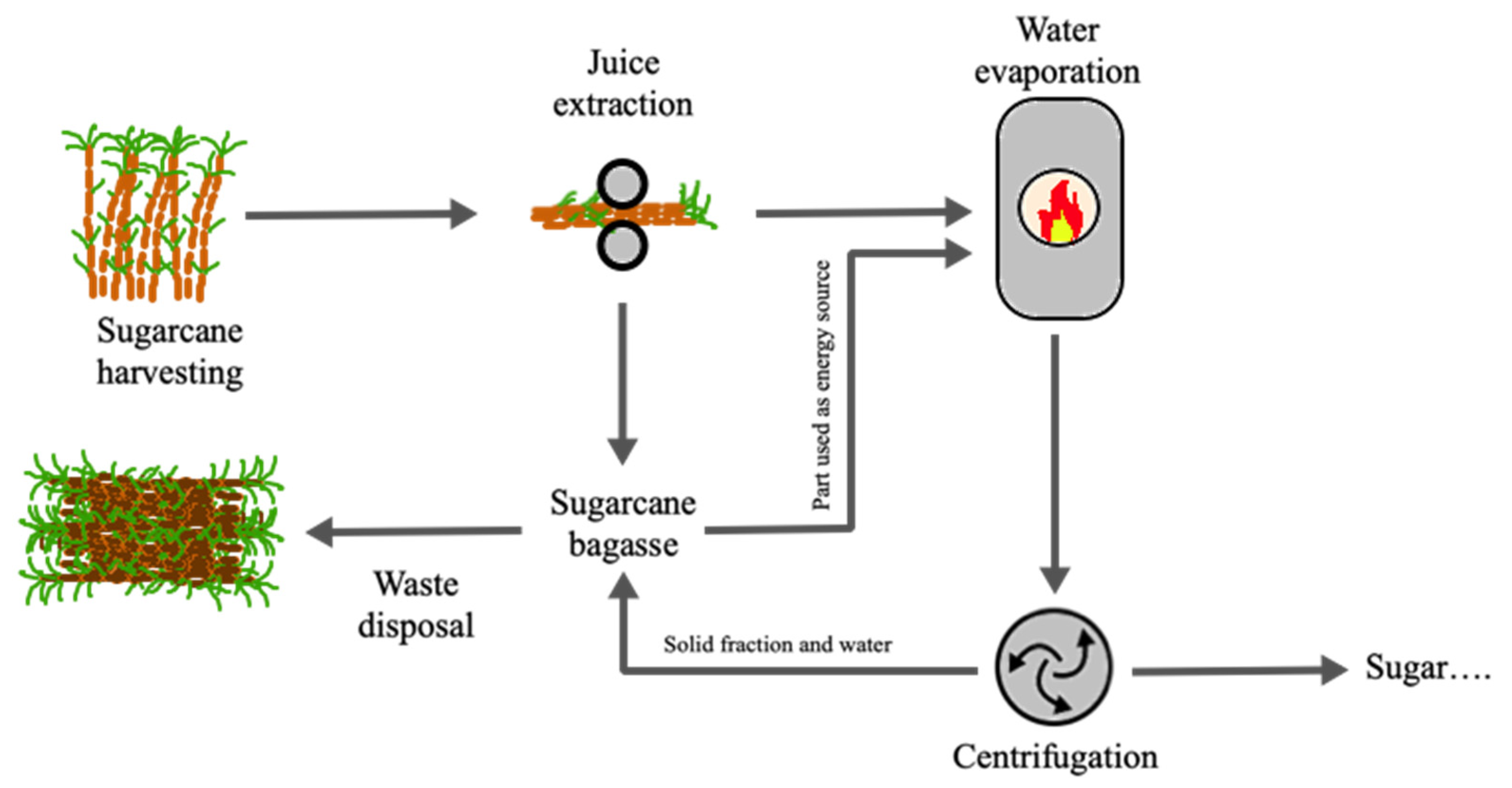

There are many studies on carbon fiber production using lignin extracted from sugarcane bagasse and many properties of carbon fibers produced are still under study. The range of work done with lignin as a raw material is quite wide and there is a tendency to increase due to the availability of biomass generated in the mills and the necessity. Sugarcane bagasse is the solid residue that remains after sugarcane a C4 plant has been crushed and the juice removed.

In an ideal sugar mill the maximum amount of sucrose would be extracted during the milling process with little left in the sugarcane bagasse. Hence the bagasse will represent a predominately lignocellulosic feedstock. The plant is the largest stand-alone biomass plant in the Philippines registered with the Department of Energy DOE.

It runs on bagasse a byproduct of sugarcane. Villar in her speech said the new plant is a welcome addition to the operations of the VMCs business. Recently the Philippine government passed the Biofuel Act of 2006 or Republic Act 9367 which created a certain market for ethanol investors in the Philippines and paved the way for the development of a new industry.

Sugarcane is expected to be the predominant source of feedstock for ethanol production. There is abundant opportunity for the wider use of bagasse-based cogeneration in sugarcane-producing countries. It is especially great in the worlds main cane producing countries like Brazil India Thailand Pakistan Mexico Cuba Colombia Philippines and Vietnam.

Yet this potential remains by and large unexploited. Published by Martha Jean Sanchez Sep 21 2020 In 2019 the value of sugarcane produced in the Philippines amounted to approximately 35 billion Philippine pesos. For every 10 tonnes of sugarcane crushed a sugar factory produces nearly three tonnes of wet bagasse.

Its challenging to use this byproduct directly as a fuel because of the high moisture content typically 4050 percent. Instead bagasse is typically stored prior to further processing. Historically the Philippines was famous for its production of sugar.

During Spanish and American ruling era the local sugarcane industry had boomed under large sugarcane plantations which assisted the countrys economic growth. Sugar was one of the important agricultural commodities and its largest importer was the United States. The data shows that approximately 59 of energy used for boilers in sugar processing provided by 365000 barrels of imported bunker oil can be displaced by.

This chart shows bagasse production details by country. Bagasse is the fibrous matter that remains after sugarcane or sorghum stalks are crushed to extract their juice. It is used as a biofuel and in the manufacture of pulp and building materials.

Agave bagasse is a similar material that consists of the tissue of the blue agave after extraction. Sugar is mostly extracted from sugarcane 80 and sugar-beet 20 which means about 144 million metric tons sugar has to be processed by sugarcane in 2017-2018. Throughout the worldwide sugar industry sugar production is increasing with the development of countries.