The development of austenitic stainless steels with excellent antibacterial property would expand the applications of such steels. Silver antimicrobial stainless steel Introduction There is increasing interest in materials that possess antimicrobial properties.

Kawasaki Steel has developed Ag-bearing stainless steels having an antibacterial property namely an effect of suppressing the growth of bacteria in response to the recent tendency to emphasize.

Stainless steel antimicrobial properties. 5 rânduri Stainless Steel. Kills more than 999 of bacteria that cause infections. Stainless Steels employs the safest anti-microbial properties for Operating Room and Healthcare equipment.

Stainless Steel is best for healthcare operating room equipment Utilization of Stainless Steel Equipment instead of Solid Surfaces greatly reduces HAI hospital acquired infections and SSI surgical site infections. Coating it with 316L stainless steel and developing its antibacterial performance. Austenitic stainless steel type AISI 316L is the only stainless steel alloy used as biomedical material 3.

Similar to titanium alloys this type of stainless steel also hows sgood corrosion resistance and biocompatibility properties. An austenitic antibacterial stainless steel formulation provides a high strength highly corrosion resistant antimicrobial product at a relatively low cost wherein antimicrobial performance is. W e designed the series combining the best stainless steel grade 316l and the best antimicrobial material copper to produce high quality products in terms of mechanical and quality properties with the antimicrobial defense against a range of pathogens including mrsa s.

Coli that only copper can offer. Stainless steel SS is the iron-based alloy containing at least 105 of chromium Cr which allows for corrosion pr evention and improves mechanical properties 1. F irst SS implants.

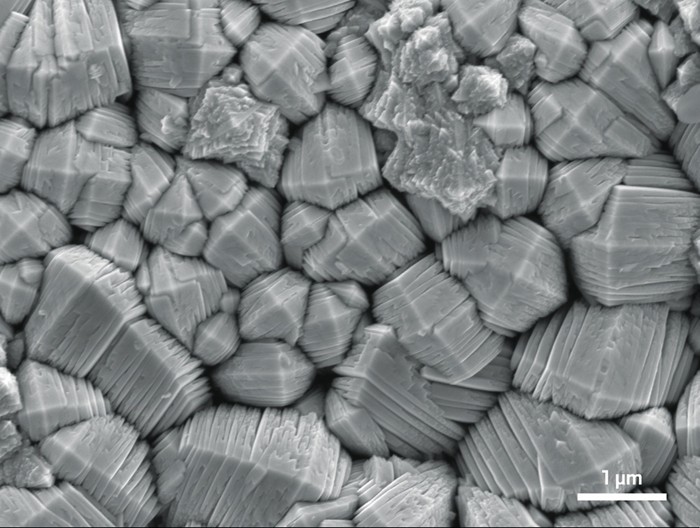

The search for anti-bacterial stainless steel has therefore focused on providing a reservoir of bioavailable silver or copper atoms concentrated only at the metal surface. Historically this challenge has been approached either by the use of very thin implanted layers or by the deposition of soft polymer-based coatings. Austenitic stainless steels such as SUS 304 are widely used because they exhibit superior corrosion resistance and workability.

The development of austenitic stainless steels with excellent antibacterial property would expand the applications of such steels. In the past some organic coatings have been used as antibacterial agents. The combined sputtering back-deposition and diffusion allows the introduction of silver into a stainless steel surface along with nitrogen and carbon.

The silver acts as the bacteria killing. AISI 304 Stainless Steel UNS S30400 AISI 304 stainless steel UNS S30400 is the most widely used stainless steel containing 18-20 Cr and 8-105 Ni and also known as 18-8 stainless steelType 304 is non-magnetic under annealing conditions but after cold working such as stamping stretching bending rolling part of the austenite structure may be converted into martensite and. The 316L stainless steel containing an appropriate amount of silver has an excellent antibacterial efficacy to S.

Aureus and its microbiological corrosion resistance is improved while an excessive silver is prone to form segregation and degrade the corrosion resistance. Kawasaki Steel has developed Ag-bearing stainless steels having an antibacterial property namely an effect of suppressing the growth of bacteria in response to the recent tendency to emphasize. The processed stainless steel demonstrated improved antibacterial properties for both Gram-positive and Gram-negative bacteria significantly impeding biofilm formation during the in vitro study.

Also the processed stainless steel showed better compatibility with human fibroblasts manifested through apparent cell spreading and proliferation. Composed of about 88 iron and 12 chromium stainless steel does not impede the growth of bacteria. Stainless steel can also develop microscopic scratches and indentations from regular wear and tear.

This leaves areas where viruses and superbugs can escape cleaning materials. In addition stainless steel is cleaned likely only once a day. In this review strategies for improving the antimicrobial properties of stainless steel SS are presented.

The main focus given is to present current strategies for surface modification of SS which alter surface characteristics in terms of surface chemistry topography and wettabilitysurface charge without influencing the bulk attributes of the material. Ification of 316L stainless steel SS which is widely applied in medical field has garnered considerable attention to enhance its antibacterial property 911. Presently the antibacterial mechanism of 316L SS is mainly based on the dissolution of Ag Cu or Zn ions 912 which is limited by several factors such as the.

An austenitic antibacterial stainless steel formulation provides a high strength highly corrosion resistant antimicrobial product at a relatively low cost wherein antimicrobial performance is dramatic and greater mechanical properties and corrosion resistance are achieved as well. Silver antimicrobial stainless steel Introduction There is increasing interest in materials that possess antimicrobial properties. In medicine and in dentistry biomaterials impregnated with various types of antimicrobials have been in use for many years 8 9 12 18.

The antimicrobial compounds used include traditional antibiotics as.