Cotton fibers and fabrics being natural cellulose polymers are biodegradable under aerobic conditions. Cotton quality mainly fibre length and diameter is largely dependent on genetics.

Uniformity fiber elongation maturity ratio and short fiber index.

Cotton fibre quality parameters. The premium range is 38 to 45 and the base range is 35 to 49 G5 and discounts apply for cotton with a micronaire outside the base range. Discounts for low micronaire can be substantial. Fibre strength is highly dependent on the variety although environmental conditions can have a.

Uniformity fiber elongation maturity ratio and short fiber index. Analysis of variance depicted considerable variation in these seven main fiber quality traits among sixteen cotton genotypes. Fiber length ranged from 1970 mm to 3350 mm with mean value of 2616 mm.

Fiber fineness was variable with average micronaire reading 36. Differences in fiber strength also ranged from 1876 to 2980 gtex. Cotton with a low length uniformity index has a high variance in fiber length which can make processing difficult and ultimately result in lower-quality yarn.

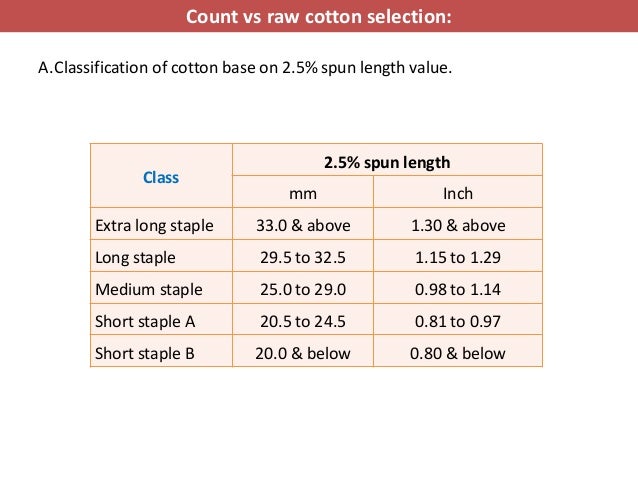

The ratio between the mean length of fibers and the upper-half-mean length of fibers is referred to as the length uniformity index. 50 SL means at least 50 of total fibers have length exceeding this value. 25SL Spun Length means at least 25 of total fibers have length exceeding this value.

Spinning Count does not depend on staple length only. It also depends on fineness and processing machinery. Parameters for categorizing cotton quality.

Fineness count Fibre length staple length Fibres tensile strength Fibre elongation Fibre uniformity CV of diameter and Fibre maturity indexratio. Fiber length and other parameters are achieved for 16-18 days. Cellulose is deposited inside the fiber for the next 22-50 days.

The balls become dry and burst naturally when the cellulose deposition is finished. Picking period of the balls for 1-3 month manually or by machine. The fibers are collected by ginning.

The fibril structure of cotton fiber consists Cuticle. The properties of cotton being a natural fibre vary in nature though it is expected that for a particular variety of cotton major fibre properties such as fibre length strength and fineness will be within a certain range. Other properties such as extension at break maturity and fibre-to-fibre friction can also modify the yarn properties.

Hence getting an ideal cotton fibre as per the predicted fibre parameters is much. Cotton quality mainly fibre length and diameter is largely dependent on genetics. Fibre maturity properties are also under genetic control but as they depend on photosynthate deposition in the cell wall they are more sensitive to environmental.

Cotton fiber quality is complex interaction of genetics and physiology of plant under prevailing environment during production season Ali et al 2008. Different micro environments have shown. Cotton Vs Polyester Fibre Cotton Polyester Advantages.

Fine soft high moisture absorption skin-body friendly eco-friendly renewable hygienic biodegradable easy dyeability good air permeability. High trash and dust weak and immature less elongation high variability in. Learn how US Upland Cotton is Classified.

Fiber Length Length Uniformity Fiber Strength Micronaire Color Grade Trash Leaf Grade Extraneous Matter Module Averaging. Fiber Properties Physical And Chemical Properties of Cotton. Cotton fiber is a cellulosic fiber.

It has worldwide popularity for its variety of use. Cotton fiber is the most used fibers for producing various types of fabric through all over the world. Bahawalpur Pakistan origin cotton fiber.

The cotton was process for fiber formation and fiber quality was evaluated on the basis of micronaire moisture trash floating fiber staple length and uniformity ratio values and compared with MTM standard fiber quality values. The micronaire values were higher than the MTM values from January to August and within acceptable range from September to. According to the general definition quality is characterized by several properties expressing the ability of a product to fulfill the functions it was designed for.

The degree of quality complex. Organic cotton fiber classification guide 4 Cotton Classification Classification is used to determine the quality of the cotton fiber in terms of length uniformity strength micronaire and color. Cotton classification and quality can also be affected by trash content leaf grade and the presence of extraneous matter.

Cotton fibers technically are trichomes or hairs. Generations of breeding have developed varieties that concentrate production into fibers with desirable qualities of color length strength and density. Fiber that doesnt meet a particular quality standard is subject to deductions which result in a reduced price paid per pound of lint.

Cotton fibers and fabrics being natural cellulose polymers are biodegradable under aerobic conditions. Independent lab results have also shown that cotton is compostable. In the case shown below 100 cotton wet wipe hydroentangled fabrics were tested for compostability using ASTM method 6400.

Characterize single cotton fiber quality parameters such as fineness maturity and micronaire. The overall objective of this research was to conduct a fundamental study of the optical properties light diffraction of individual cotton fibers with the interaction of a monochromatic light beam. Diffraction patterns generated from the interaction of each.