ME EN 7960 Precision Machine Design Linear Motions Systems 3-15 Lead Screws Lead screw principle has been used for centuries to convert rotary motion into linear motion with a high transmission ratio Modern lead screw driven servo system. Jun 21 2018.

If a precise speed is not a requirement of the movement.

Converting rotary motion to linear motion. Lead screws are a common technology used to convert rotary motion into linear motion and are often used to provide actuation to a set of linear bearings. Plastic lead screw nuts are an excellent alternative to ball screws in many applications where extreme precision micron level is not required. Rotary motion can be converted into linear motion by using a screw.

This volume introduces an automation clever mechanism that allows control of linear motion in various ways by adopting different types of screw structures. Threaded and tapped screws are used as a cam. One way to convert rotary motion into linear is through a leadscrew and nut assembly inside the motor.

This approach lets you use a drop in motor in your designs eliminating the need for external mechanical linkages. This schematic shows the insides of such a motor. Lead screws are a common technology used to convert rotary motion into linear motion and are often used to provide actuation to a set of linear bearings.

For Des Inv 90-2. Mechanisms to convert linear motion to rotational. There are different mechanisms around the most common of all crankshafts.

What is the best mechanism for your problem coupling the opening of the door to the sliding of the can. I dont think you can use a rack-pinion mechanism unless you have pinion with big radius. IMHO the best mechanism for your need should be a 1DOF mechanism mechanism.

I need to convert 762cm3in linear motion from an actuator to 150-180 150 is minimum rotary motion. I am aware of the existence of gears but would probe here to see if there is some simpler method. I could use rods mounted in some way.

It has to be compact and rugged however. Id also be interested in formulas for this type of conversion. How to transform rotary motion into linear Think about the process when selecting feed-screw devices.

By Tom Stevic contributing editor. Jun 21 2018. In the world of machine controls linear motion is the name given to the process of moving some object in a straight line usually with a programmed speed and to a defined position.

If a precise speed is not a requirement of the movement. ME EN 7960 Precision Machine Design Linear Motions Systems 3-15 Lead Screws Lead screw principle has been used for centuries to convert rotary motion into linear motion with a high transmission ratio Modern lead screw driven servo system. Converting Rotation To Rotary And Linear Reciprocating Motion - YouTube.

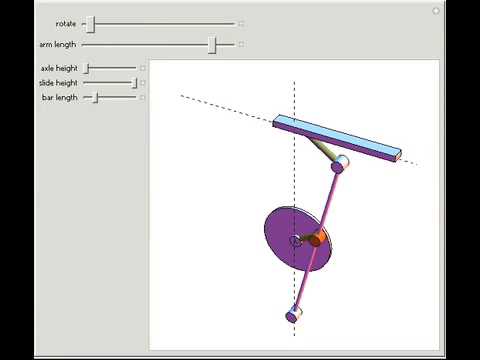

Converting Rotation To Rotary And Linear Reciprocating Motion. Jim Maerzke describing the platform technology of the LRM. How to convert 6mm 14 of linear travel into 90 degrees of rotary motionThis is just me proving the theory for a woodworking project Im working on.

In a mechanism for converting rotary motion into linear motion a large thrust can be generated by arranging a revolving roller 21-24. 121-24 provided on an outer peripheral surface thereof with a roller groove 21b-24b which makes a round on a holder 3 so as to make the revolving roller 21-24. 121-124 mesh with a rack thread 1a of a centrally positioned rack rod 1 revolving the.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. A rotary to linear reciprocating motion converter includes an endless chain 5 coupled to spaced drive and driven sprockets 3 4 an output rod 8 slidably disposed on a guide bar 6 via a slide member 7 and a connecting rod 16 coupled between a chain link and the upper end of the output rod by pivot pins 17 18. Rotational moments about the guide bar are absorbed by a roller 11 journalled on a.