Of a thrust collar secured to the rotating shaft thrust bearing surface and guide bearing all enclosed in an oil bath. Install retainer washer in groove in liner base.

Babbitt Face The thickness of the babbitt has also been opti-mized to increase compressive strength of the babbitt while.

Babbitt faced collar bearings. November 14 2018. Babbitt bearings are found in pumps motors fans industrial equipment and turbines. Basically they support the weight of the shaft and provide a non-damaging surface to the high-speed shaft that rotates.

The lining of a bearing is bonded with Babbitt which is a soft alloy featuring a low-melting point. Babbitt metal or bearing metal is any of several alloys used for the bearing surface in a plain bearing. The original Babbitt alloy was invented in 1839 by Isaac Babbitt in Taunton Massachusetts United StatesHe disclosed one of his alloy recipes but kept others as trade secrets.

Other formulations were developed later. Like other terms whose eponymous origin is long since deemphasized. Regions of babbitt material creep in a hot-running region of a cylindrical bearing.

Occurring more often than creep wiping represents surface displacement due to contact between the rotating journal thrust collar and the babbitt surface Figure 6. Press Babbittrite on the face and corner of the outer edge of the collars. Assemble two inner collars on the babbitting mandrel.

Place brass spacers in bearing cavities to center the mandrel. Place mandrel with two inner collars onto brass spacers 516 for 25. Babbitt bearings are found on motors fans pumps turbines generators and other industrial equipment.

The bearings are designed to support the weight of the shaft while providing a non-damaging surface for the high speed rotating shaft. In a Babbitted bearing the lining of the bearing is bonded with Babbitt a low melting-point soft alloy. Babbitt Face The thickness of the babbitt has also been opti-mized to increase compressive strength of the babbitt while.

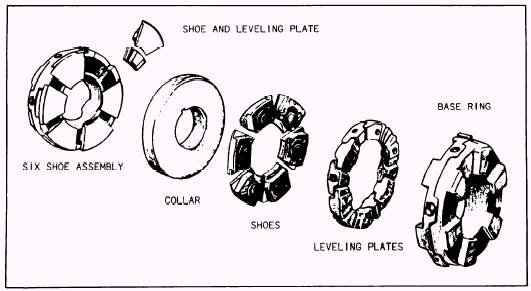

The thrust bearing face and the operating thrust collar. The ability of a shoe to pivot as well as to tilt increases load-carrying capability at all shaft speeds. Thrust bearing to the thrust collar.

With the bearings discussed pre. Babbitt face but no closer than 0030 in from the bond line. As an example for babbitt 0060 in thick the sensor should be 0090 to 0100 from the babbitt face 0060 babbitt plus 0030 minimum.

Babbitt Face The thickness of the babbitt has also been optimized to increase compressive strength of the babbitt while maintaining the very desirable embedability characteristic of babbitt. This material allows small amounts of foreign particles that are in the lubricating oil to embed themselves in the babbitt rather than score or damage the rotating collar. Babbitt bearings were used widely in heavy gasoline engine powered equipment.

These types of equipment dealt with heavy load requirements such as milling planing and chipping trees. By 1949 metallurgy advances from World War II had rendered the Babbitt bearing practically obsolete for use in automobiles. Babbitt Bearing Failure Mechanisms zElectromagnetic discharge damage zOil burn due to high temperature zLoss of bond between babbitt and base metal.

ZChemical attack zPivot wear in tilting pad bearings. Babbitt Bearing Failure Mechanisms zDamage caused by unloaded pad flutter. Of a thrust collar secured to the rotating shaft thrust bearing surface and guide bearing all enclosed in an oil bath.

Oil in the bath is generally cooled either by a water jacket cast in the casing or by cooling coils submerged within the oil. Low duty applications are air cooled. The babbitt face of a tapered-land thrust bearing has a series of fixed pads divided by radial slots.

The leading edge of each sector is tapered allowing an oil wedge to build up and carry the thrust between the collar and pad. By Bill Strecker Kingsbury Inc. Pumps and Systems February 2007.

When evaluating bearing distress the babbitted shoe surface is commonly the only area that is examined. Although a great deal of information can be extracted from the babbitt appearance additional information exists. Pouring the babbit for the bearings on my 1929 Oldsmobile.

This is something no one does anymore unless you happen to be rebuilding an antique car yourself. The bearing surface is sacrificed with Babbitt actually becoming the lubricant and the shaft surface is preserved in case there is a loss of lubrication or other operating anomaly. In the 17th century Robert Hooke began utilizing bell metal as a bearing surface material.

Bells were often formed with a bronze alloy that usually included. Press the babbitted face against the thrust collar and rotate plate around shaft into liner cavity. Install retainer washer in groove in liner base.

Rotate plate until stopped by retainer washer. Place the other thrust plate half half with two milled slots in steel back against thrust collar making sure babbitt faces thrust collar. The use of PTFE-faced pads in large vertical axis hydro-generators was pioneered in Russia in the 1970s prompted by a series of failures of conventional babbitt-faced bearings.